1. Introduction to Textile Defects

From fiber raw materials to the final woven fabric, it is necessary to go through processes such as spinning, weaving, dyeing, and printing. Each engineering stage requires multiple continuous processes to complete. In each level of processing, improper setting conditions, negligence in personnel operations, or mechanical failures may lead to appearance defects in the product. Theoretically speaking, the more processing levels there are, the higher the probability of defects occurring. Such defects visible in the appearance of the fabric are called Fabric Defects. However, there are also defects that show no abnormality in the greige (raw) state but appear significantly after scouring, bleaching, and dyeing; these are generally called Latent Defects.

There is a common proverb in China: "The more you do, the more mistakes you make; the less you do, the fewer mistakes you make; do nothing, and you make no mistakes." Although this phrase is out of step with the modern work spirit, it is very practical when applied to the defects generated by multi-level textile processing.

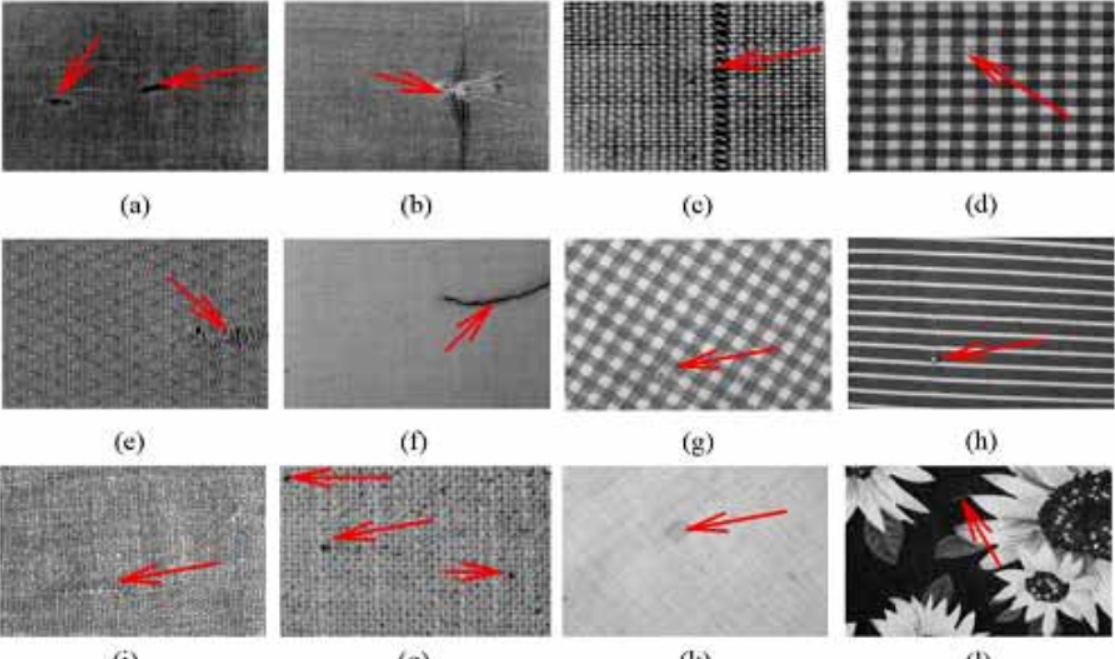

There are few perfect things in the world. Spinning engineering will produce defects in the raw yarn, such as Neps and Slubs; weaving engineering will produce defects in the greige fabric, such as Mispicks and Broken Ends; dyeing and printing engineering will produce defects in the finished cloth, such as Dye Spots and Tailing or Ending. High-quality finished fabrics should have very few defects.

If a certain finished fabric has many defects, whether used for clothing, bedding, or other daily necessities and decorations, it will affect its beauty and reduce its value.

Appearance Characteristics and Causes of Fabric Defects

From fiber to finished fabric, the processing stages can be divided into four major stages: Spinning, Weaving, Scouring & Bleaching, Dyeing, Printing, and Finishing.

The following describes the defects that may occur in each stage using common factory names, categorized by their appearance characteristics and causes:

Those belonging to fiber raw materials and yarn causes;

Those belonging to weaving causes;

Those belonging to dyeing, printing, and finishing causes;

Those whose causes are difficult to attribute or related to professional processing.

2.1 Belonging to Fiber Raw Materials and Yarn Causes

(1) Nep

Appearance: The fabric surface shows cotton fiber clumps similar in size to a joint, which are spun into the yarn. If pulled off, the yarn appears broken or near breaking. Roving spun from low-grade raw cotton often has this defect.

Causes: 1. Dead cotton fiber clumps in the raw cotton were not thoroughly removed during the opening/cleaning process. 2. During carding, the wires on the cylinder or flats are not sharp enough, or the gauge between them is set improperly, failing to exert full carding action.

(2) Seeds

Appearance: Very small black or dark non-fiber fragments/spots on the surface of pure cotton or cotton-blend greige fabric.

Causes: 1. During the ginning process (separating fibers from seeds), fiber ends carry seed hulls, or seeds are crushed and mixed into the raw cotton. 2. The opening/cleaning process fails to thoroughly remove seed hulls.

(3) Slub

Appearance: An occasional short segment on the warp or weft of the fabric, about 5~20mm long, which is thicker than the normal yarn diameter and has fewer twists.

Causes: 1. Uneven density within the roving fibers fed during fine spinning, with small, dense spindle-shaped fiber bundles. 2. The rubber rollers and aprons of the spinning frame fail to uniformly hold the fed roving.

(4) Flyer

Appearance: Similar to a slub, but thicker and not as elongated; fibers are in a clump. Slightly untwisting the yarn will not cause it to break.

Causes: Fiber clumps floating in the air in the spinning room, or clumps accumulated on the machine table near the feeding area, become wrapped around the yarn.

(5) Cockled Yarn

Appearance: Periodic large thick knots within a segment of yarn roughly the length of the fabric width. The thickness change resembles bamboo joints; common in the weft of coarse fabrics, hence also called "Bamboo Weft."

Causes: Drafting rollers of the spinning frame are set too tight, roller covers are too loose, or there are occasional extra-long fibers in the fed roving.

(6) Uneven Yarn

Appearance: Observed from the length of the fabric, the woven yarn shows uneven thickness. Mostly occurs in the weft.

Causes: Yarn produced by the spinning frame has alternating thick and thin sections due to drafting mechanism failure or poor performance.

(7) Cloud of Weaving

Appearance: Significant irregularity in weft count; during weaving, thick or thin sections happen to be concentrated and arranged together, forming patches like floating clouds.

Causes: Regular unevenness in the weft yarn, where the arrangement during weaving causes thick or thin sections to gather.

(8) Fiber Spot

Appearance: In dyed fabrics, a very small amount of fiber in the fabric does not take color or is dyed lighter, appearing whitish.

Causes: 1. Presence of dead cotton fibers. 2. During spinning, a small amount of polyester fiber is mixed in due to negligence or poor control; if non-disperse dyes are used or non-high-temperature dyeing is applied, the polyester will not be colored.

(9) Different Lots

Appearance: In synthetic fiber or textured yarn fabrics and blended fabrics, the yarn count and density meet specifications, but after dyeing, there are distinct differences in color depth between warp or weft yarns.

Causes: Blended yarns used during weaving have different blending ratios despite meeting count and density specs; differences in color depth appear after dyeing.

(10) Poor Yarn Steaming

Appearance: For a piece of E/C blend fabric, after desizing, scouring, and bleaching, the fabric width shows periodic changes in width.

Causes: After blended yarn is wound, it needs high-pressure saturated steam treatment in a closed container to stabilize its physical properties. If the temperature or time is insufficient, the yarn is not set; after scouring during bleaching, the fabric surface shows alternating tight and loose sections horizontally.

(11) White Point (White Spot)

Appearance: Undyed fiber clumps appear on the surface of dyed fabric, especially prominent in medium-to-dark colors.

Causes: Mostly occurs in low-to-medium grade cotton dyed fabrics. Neps formed by dead cotton fibers in the yarn cannot be removed during scouring or mercerization. Due to the poor dyeability of dead cotton, it remains undyed and appears as white spots. Recently, it frequently occurs in fabrics woven from pure cotton open-end spinning below 20Ne.

2.2 Belonging to Weaving Causes

2.2 Belonging to Weaving Causes

(1) Wrong Yarn

Appearance: Continuous horizontal loops in knitwear made of yarn thicker or thinner than the specified yarn. Usually a single strand, but occasionally multiple strands. Density and thickness differ from normal.

Causes: During knitting, the operator mistakenly uses yarn of a non-designated count or denier. Using thinner yarn makes the fabric sparse; thicker yarn makes it dense.

(2) Wrong End

Appearance: A single or multiple warp yarns in woven fabric are of non-designated thickness. Thinner is "Fine End"; thicker is "Coarse End."

Causes: Wrong yarn count picked during warping. This is often a full-piece defect.

(3) Wrong Pick

Appearance: One or multiple continuous weft yarns in woven fabric are of non-designated thickness. Thinner is "Fine Pick"; thicker is "Coarse Pick."

Causes: Wrong yarn count used in weft bobbins or shuttleless loom cones. Often difficult to detect on automatic looms.

(4) Wrong Weaving (Organization Error)

Appearance: Incorrect weaving method; the fabric texture differs from the design (e.g., left twill woven as right twill).

Causes: Usually caused by heddle threading errors, jacquard card errors, or warp arrangement errors.

(5) Wrong Draw (Double End)

Appearance: Two adjacent warp yarns are drawn together and woven as one; that "yarn" (actually two) appears exceptionally thick. This is a full-piece defect.

Causes: Negligence during warping or sizing (sticking together), or threading two yarns into one heddle.

(6) Mispick (Double Pick)

Appearance: Two or more weft yarns woven into the same shed. Length varies; most common across the full width or near the edges (about 10cm).

Causes: Full-width: restarting without checking the shed after a stop, or detector failure. Non-full-width: insufficient catch-cord length, dull cutters, or failure to clear yarn tails.

(7) Set Mark, Fine (Rare Alley)

Appearance: Weft density is sparser than specified. A section of weft gradually becomes sparser and then returns to normal, forming a thin-looking band.

Causes: Filling detector failure (looming continues without weft), improper warp tension, or tension being too tight before restarting.

(8) Set Mark, Coarse (Dense Road)

Appearance: Weft density is denser than specified, forming a tight-looking band.

Causes: Improper warp tension control or tension being too loose upon restarting.

(9) Pick-Out Mark

Appearance: Traces left on the fabric after improper removal of weft yarns.

Causes: When removing a wrong pick or set mark, the warp is frayed by friction, creating a hairy area after re-weaving.

(10) Broken End

Appearance: One or more broken warp yarns, increasing the distance between neighbors. In plain weave, it looks like two yarns are together; in twill, the pattern is interrupted.

Causes: Stop motion failure to detect a broken warp.

(11) Broken Pick

Appearance: Weft yarn breaks, but the distance between ends is very small. Generally not prominent.

Causes: Yarn breaks during insertion but continues for a moment, or breakage occurs while removing slubs/flyers.

(12) Centipede (Missing Pick)

Appearance: Occurs only in twill; warp yarns float over the surface at the same position in each repeat, resembling centipede legs.

Causes: A missing weft yarn causes certain warp yarns to float over two picks consecutively.

(13) End Snarl

Appearance: A single warp yarn is kinked/twisted into the fabric. Common in high-twist yarns.

Causes: One warp yarn was excessively loose during warping.

(14) Filling Snarl

Appearance: Weft yarn is kinked/twisted into the fabric.

Causes: Kinks already present in the bobbin, improper bobbin formation, low tension, or unclear shed.

(15) Reed Mark

Appearance: Large intervals between warp yarns where the weft shows sawtooth-like marks from the reed.

Causes: Bent or loose reed teeth, or excessive tension on specific warp yarns.

(16) Temple Mark

Appearance: Needle punctures or scraping marks 2~5cm from the selvage. Severe cases cause wavy weft.

Causes: Wrong needle size, or the temple ring is stuck/not rotating smoothly.

(17) Smash

Appearance: Numerous broken warp yarns near the selvage. After repair, the surface shows many tails and irregular density.

Causes: Shuttle trapped in the shed. Prevented by shuttleless looms.

(18) Reedness (Square Eye)

Appearance: Warp yarns crowd in pairs, leaving large gaps between pairs, forming a checkerboard-like square pattern.

Causes: Shed angle too large, uneven tension between layers, or uneven reed density.

(19) Yarn Tail

Appearance: Yarn ends protruding from the fabric surface or edge.

Causes: Failure to trim tails after tying knots or edge cutter failure.

(20) Knot

Appearance: Large, hard knots protruding from the fabric surface.

Causes: Knots tied after breaks are too large.

(21) Float

Appearance: Warp or weft yarns skip over the surface instead of interlacing.

Causes: Small shed angle, uneven heddles, or loose warp yarns.

(22) Spider Web

Appearance: Severe float where multiple adjacent yarns lack interlacing points, forming a net.

Causes: Same as float, but more severe.

(23) Weaving Hole

Appearance: Broken warp and weft forming holes. Common in high-density fabrics.

Causes: Shuttle friction or temple roller tearing.

(24) Slack End (Guttering)

Appearance: A warp yarn arches up at interlacing points. Known as "Jin Li" (Muscle Standing) in factories.

Causes: Low tension on a single warp yarn or excessive looseness after repair.

(25) Slack Filling

Appearance: A weft yarn arches up at interlacing points. Generally not obvious.

Causes: Low tension on a single weft yarn.

(26) Tight End

Appearance: A warp yarn appears straighter and recessed. Obvious in twill/satin; can cause fabric unevenness.

Causes: Excessive tension on a single warp yarn or pulling too tight during repair.

(27) Tight Filling

Appearance: A weft yarn appears straighter and recessed. Rare and less obvious than tight end.

Causes: Resistance during weft unwinding.

(28) Gap (Crack)

Appearance: Adjacent yarns form a curved gap.

Causes: Failure to comb yarns back into place after removing slubs or kinks.

(29) Mending Mark

Appearance: Traces remaining after repairing severe defects.

Causes: Yarn arrangement remains abnormal/wavy after mending set marks or broken ends.

(30) Teariness (Pushing Yarn)

Appearance: Weft yarns are not straight and curve in one direction over a small area. Common in fabrics with filament warp and staple weft (e.g., Oxford).

Causes: Improper design causing yarns to slide, low weft density, or excessive clamping during finishing.

(31) Broken Selvage

Appearance: Three or more broken selvage yarns, causing the edge to split.

Causes: Excessive selvage tension or improper temple usage.

(32) Tight Selvage

Appearance: Edges are straight but the fabric body nearby is wrinkled; the fabric doesn't lie flat.

Causes: Selvage warp tension is too high.

(33) Slack Selvage

Appearance: Wavy edges (lettuce edge); fabric body is flat but edges are wrinkled.

Causes: Selvage warp tension is too loose.

(34) Sawtooth Edge

Appearance: The outermost edge of the selvage is jagged.

Causes: Too few selvage yarns or excessive weft tension.

(35) Uneven Let-off

Appearance: Periodic density changes in the weft, looking like alternating thin and thick bands.

Causes: Unstable warp let-off tension or rate.

(36) Dropped Stitch

Appearance: In knitting, the distance between two vertical columns of loops is larger than normal.

Causes: Yarn fails to be caught by the needle.

(37) Yarn Arrangement Error

Appearance: Yarn fails to follow the designed arrangement in stripes/checks.

Causes: Incorrect number of warp/weft yarns in the repeat.

(38) Starch Lump

Appearance: Dried starch blocks or spots on the greige cloth.

Causes: Incomplete gelatinization or worn size rollers.

(39) Mildew Spot

Appearance: Grey-black or reddish spots on the greige cloth.

Causes: High humidity or long storage time.

2.3 Belonging to Dyeing, Printing, and Finishing Causes

(1) Gasoline Spot (Oil-drop Dye Spot)

Appearance: Occurs in E/R blends; oil-drop-like spots darker than normal. Fiber tips in dark areas are fused into beads.

Causes: Uneven singeing; fused tips absorb more dye.

(2) Fuzz (Nap)

Appearance: Fine fuzz remains on the fabric after finishing, differing in color tone.

Causes: Insufficient singeing or excessive jet pressure in liquid dyeing.

(3) Imperfect Penetration of Dye

Appearance: Surface shows deep/light cloud-like patches.

Causes: Insufficient desizing/scouring or rapid heating with a low liquor ratio.

(4) Scouring Spot

Appearance: Yellowish traces of impurities and scouring agents. Scraps fall off when scraped with a nail.

Causes: Scouring agent coagulation or insufficient washing.

(5) Bleached Hole

Appearance: Small holes appearing after peroxide bleaching despite normal greige cloth.

Causes: Iron ions/rust on the cloth react violently with hydrogen peroxide, breaking the yarn.

(6) Skilteriness (Color Flower)

Appearance: Irregular patches of deep and light color.

Causes: Poor pre-treatment (desizing/scouring).

(7) Mist

Appearance: Patchy dye spots with unclear outlines and irregular distribution.

Causes: Splashed sewage/chemicals, or water stains from delayed drying after bleaching.

(8) Color Difference (Off-shade)

Appearance: Finished color doesn't match the sample.

Causes: Inaccurate dye weighing or process mismatch with the lab dip.

(9) Dye Lot Difference

Appearance: Batch color differences between different dye vats.

Causes: Slight variations in machine performance or operation conditions between vats.

(10) Two-sidedness (Face-to-back)

Appearance: Color difference between the face and back.

Causes: Uneven heat during pre-drying or different wind speeds during resin finishing.

(11) Left-to-right Color Difference

Appearance: Gradual color change from left to right selvage.

Causes: Uneven padding roller pressure or inconsistent temperature/airflow across the machine width.

(12) Listing (Center-to-edge)

Appearance: Color difference between the center and edges.

Causes: Improper expander curvature, uneven temperature in the vat, or inconsistent center/edge pressure.

(13) Tailing or Ending (Head-to-tail)

Appearance: Color difference between the start and end of a continuous dyeing run.

Causes: Inconsistent dye affinity, unstable dye liquor, or temperature drift during drying.

(14) Migration

Appearance: Uneven color tone caused by dye moving with water toward the surface during drying.

Causes: High pickup, rapid drying, or lack of anti-migration agents.

(15) Dyestuff Spot

Appearance: Dark irregular patches.

Causes: Poor dye dissolution, impurities, or hard water.

(16) Dyeing Streak

Appearance: Differences in color tone/concentration between adjacent yarns.

Causes: Chemical variations in the synthetic fibers' dyeability.

(17) Intrinsic Luster Streak

Appearance: Bands of different luster visible under direct light.

Causes: Physical variations in fiber (crystallinity/orientation) affecting light reflection.

(18) Fabric Configuration Streak

Appearance: Color depth differences based on weave structure.

Causes: Variations in light reflection due to interlacing point distribution.

(19) Spacing Streak

Appearance: Vertical bands of color depth.

Causes: Uneven yarn density causing visual depth differences.

(20) Carrier Spot

Appearance: Droplet-like dark spots on polyester.

Causes: Poor carrier dispersion or condensed carrier dripping from the machine top.

(21) Warp Stripe (Yarn Texture Streak)

Appearance: Rain-like vertical stripes.

Causes: Variations in yarn count/twist; improper dye selection (especially green).

(22) Barry Dyeing (Filling Band)

Appearance: Horizontal bands of different colors.

Causes: Weaving set marks, uneven tension, or mixed yarn lots.

(23) Dye Spot

Appearance: Small colored specks (same or different color).

Causes: Undissolved dye particles or contamination from flying dye powder.

(24) Rope Mark

Appearance: Irregular longitudinal wrinkles/streaks from rope dyeing.

Causes: Lack of pre-setting or rapid temperature changes.

(25) Padding Mark

Appearance: Lighter color at longitudinal folds during padding.

Causes: Pre-existing creases or expander failure.

(26) Moire

Appearance: Wood-grain luster patterns.

Causes: Excessive shrinkage or over-tight winding during beam dyeing.

(27) Uneven Dyeing on Selvage

Appearance: Selvage color differs from the body.

Causes: Loose/tight selvage, edge curling, or edge oxidation during jigger dyeing.

(28) Fading of Selvage (Discoloration)

Appearance: Selvage color changes after finishing.

Causes: High pin-plate temperature causing dye sublimation.

(29) Edge Mark (Knitwear)

Appearance: Dyeing abnormality at the folded edges of tubular knits.

Causes: Deteriorated oil, long storage, or high setting frame temperature.

(30) Scorching Mark

Appearance: Lighter large creases, common in E/C blends.

Causes: Fabric sticking to a hot conveyor belt in a continuous scouring machine.

(31) Colored Spot (Contamination)

Appearance: Large irregular areas of foreign color.

Causes: Contact with wet dyed fabrics or dirty equipment.

(32) Scum Spot (Foam Pollution)

Appearance: Whitish traces of foam residue.

Causes: Excessive foam in the dye or reduction vat.

(33) Tarring Staining

Appearance: Dark streaks/spots from dye aggregation.

Causes: Poor dissolution or incompatible auxiliaries.

(34) Roller Contamination

Appearance: Periodic small patches of oil/chemicals/dye.

Causes: Dirty guide rollers, pressure rollers, or drying cylinders.

(35) Chemicals Staining

Appearance: Patchy discoloration or deterioration.

Causes: Infiltration of non-designated chemicals.

(36) Dyeing Stop Mark

Appearance: 2~10cm horizontal band of different color with watermarks.

Causes: Sudden machine stop during padding.

(37) Color Stain (Storage)

Appearance: Dark spots appearing after packaging.

Causes: Condensation causing dye migration in sealed packages.

(38) Pattern Blur

Appearance: Fuzzy printed lines.

Causes: Poor engraving or low doctor blade pressure.

(39) Out of Register (Printing)

Appearance: Misaligned colors in a print.

Causes: Poor screen alignment.

(40) Lack of Paste

Appearance: Missing parts of the design.

Causes: Empty paste tank or pump failure.

(41) Print Line Break

Appearance: Interrupted fine lines.

Causes: Shallow engraving or high paste viscosity.

(42) Printing Crease

Appearance: Longitudinal unprinted areas.

Causes: Fabric was wrinkled/overlapped during printing.

(43) Screen Clogging (Scrimp)

Appearance: Small unprinted spots.

Causes: Lumps in the paste blocking the screen.

(44) Bleeding (Halo)

Appearance: Blurred pattern edges.

Causes: Low paste viscosity or overlapping colors.

(45) Printing Roller Pollution

Appearance: Uniform light pollution on white backgrounds.

Causes: Poor roller surface or dull doctor blade.

(46) Doctor Blade Mark (Smear)

Appearance: Longitudinal single-color streak.

Causes: Lumps in paste caught under the doctor blade.

(47) Roller Scratch (Lining)

Appearance: Extra fine lines not in the design.

Causes: Damaged roller surface or hard debris in the paste.

(48) Tailing (Printing)

Appearance: "Drag" marks on dots.

Causes: Excessive paste or uneven tension.

(49) Chattering (Skipping)

Appearance: Periodic color depth changes.

Causes: Improper doctor blade installation.

(50) Mis-joint (Printing)

Appearance: Pattern fails to connect at screen repeats.

Causes: Poor screen making or alignment.

(51) Back Grey Seam Pollution

Appearance: Blurred horizontal bands.

Causes: Thick seams in the back grey fabric absorbing moisture.

(52) Printing Stop Mark

Appearance: 5~15cm horizontal band of mixed colors.

Causes: Machine stop without lifting rollers.

(53) Water Drop Mark

Appearance: Circular light spots with dark edges.

Causes: Condensation dripping onto fabric before finishing.

(54) Color Development Spot

Appearance: Patchy light color after development.

Causes: Incorrect concentration, uneven temperature, or incomplete oxidation.

(55) Resin Spot

Appearance: Dried hard resin patches with luster.

Causes: Poorly dissolved resin sticking to the cloth.

(56) Surface Resin

Appearance: Resin floats on top; scratches easily with a nail.

Causes: High pickup or initial drying temperature.

(57) Pilling

Appearance: Fiber balls on the surface.

Causes: Excessive surface fuzz or lack of anti-pilling agents.

(58) Split Yarn (Knitwear)

Appearance: A row of loops pulled straight.

Causes: Wrong feeding direction during setting.

(59) Shining Surface

Appearance: Unwanted gloss, common in synthetic knits.

Causes: Excessive tension during resin finishing.

(60) Uneven Surface

Appearance: Fabric doesn't lie flat on a table.

Causes: Inconsistent longitudinal/transversal shrinkage.

(61) Poor Elasticity

Appearance: Fabric fails to recover after stretching.

Causes: Poor yarn crimp or excessive heat during setting.

(62) Paper Like

Appearance: Stiff, smooth fabric with low stretch.

Causes: Low-shrinkage synthetic fibers that fail to contract.

2.4 Causes Difficult to Attribute or Specialized Processing

(1) Oil Warp / (2) Oil Weft / (3) Oil Yarn

Appearance: Specific sections of yarn contaminated with oil.

Causes: Lubricant from winding or weaving machinery.

(4) Oil Stain

Appearance: Large patches of oil.

Causes: Splashed oil during processing or transport.

(5) Water Mark

Appearance: Traces of air-dried water.

Causes: Immersion in water or traces left after washing oil stains.

(6) Chafe Mark

Appearance: Gloss/color differences from friction.

Causes: Slippage in the machine or rubbing against rough surfaces.

(7) Hole

Appearance: Cut warp and weft.

Causes: Sharp objects during transport or use of hooks.

(8) Crease (Fold Mark)

Appearance: Wide, indented grooves, common at ends.

Causes: High packing pressure, improper expansion, or non-parallel rollers.

(9) Uneven Napping

Appearance: Inconsistent length/density of pile.

Causes: Wrinkles during napping or uneven pile-warp loops.

(10) Shedding (Pile)

Appearance: Pile clusters pull out easily.

Causes: Poor weave design with insufficient pile grip.

(11) Distortion (Wavy Grain)

Appearance: Large areas of yarn shift, creating wavy density.

Causes: Low liquor ratio with high speed, or excessive expander angles.